Predictive Drilling Showcasing Game-Changing Results in the Field

Corva's Predictive-Drilling helps you deliver the lowest average cost per foot drilled by reducing dysfunction, saving trips, and automating consistent, efficient performance across your fleet. Through our collaboration with Nabors Industries and integration with SmartROS®, Corva extends rig controls and real-time data pipelines from the wellsite to:

- Reduce HMI interactions by 5,000+ per well

- Experience 35-45% higher rotary ROP vs offsets in laterals

- Reduce lateral and axial vibration up to 20%

- Save time with more one run laterals, 1.0-1.5 days faster than offsets

- Save $100,000-$150,000 per well in spread and bit costs

Explore these powerful case studies to learn more:

Collaboration

Corva Predictive Drilling Boosts ROP & Saves Client $270k per Pad

Discover how Corva's Predictive Drilling enhanced ROP by 26% and saved a Permian Basin operator $270k per pad.

Predictive Drilling

AI Powered Closed-Loop Automation Boosts ROP by 26% for Permian Well Pad

Leveraging Corva's Predictive Drilling solution working in concert with the Nabors SmartROS control system, the operator outperformed nearby offset well ROP by 26%, reduced trip time, and extended bit life.

Predictive Drilling

Predictive Drilling: A Layered Approach to Selecting Setpoints

24/7 Real-Time Monitoring: Revolutionizing Decision Making with Corva and i-TRAK™

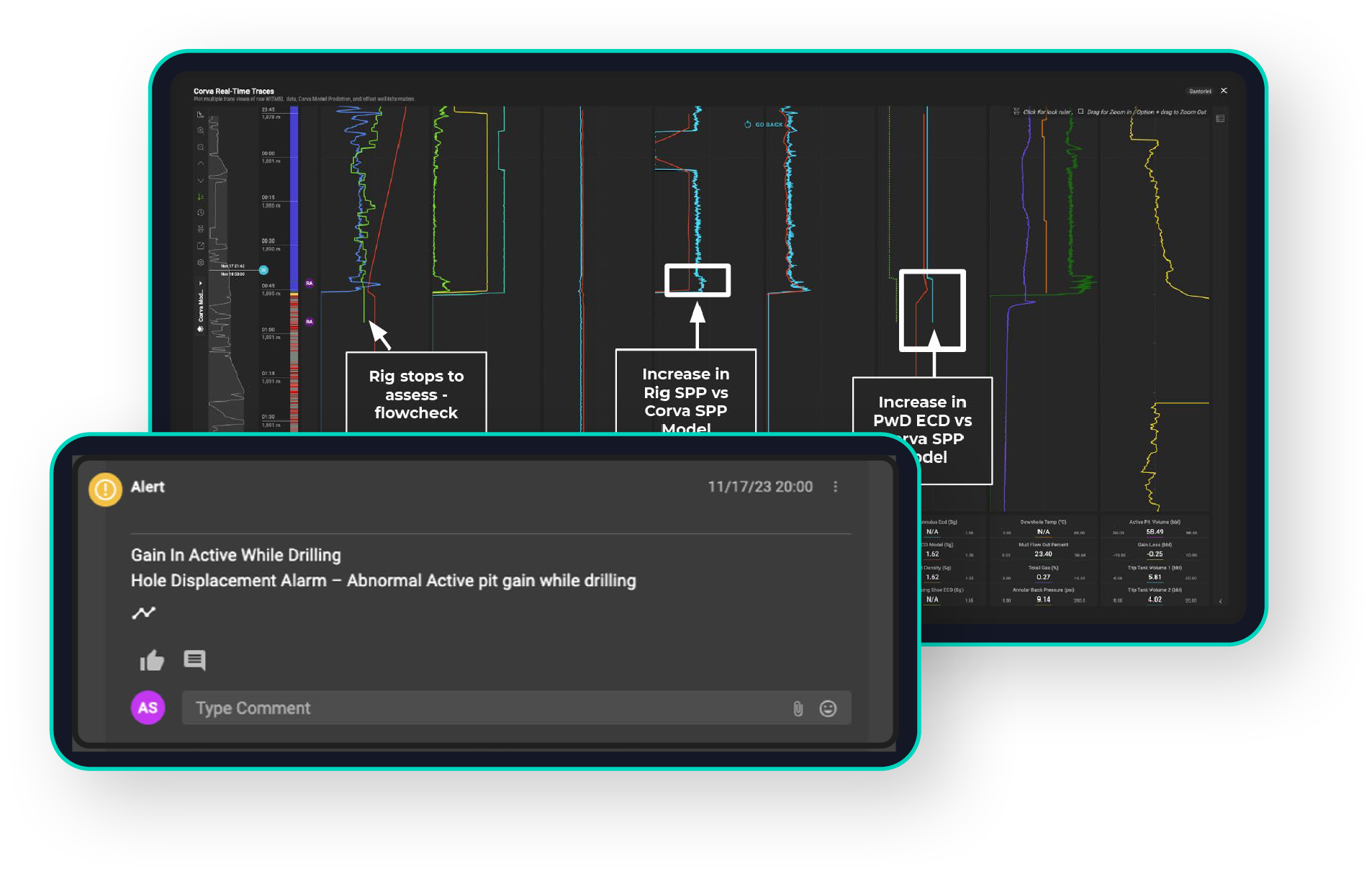

After a 10-hour unplanned outage, drilling challenges emerged, including stuck pipe and pressurized formation damage. Baker Hughes’s engineers noticed anomalies in standpipe pressure and equivalent circulating density, through Corva’s analytics. Corva Alerts on active pit gain enabled timely mitigation, preventing a well control issue. This proactive approach saved approximately $21 million in operational costs and ensured crew safety.

In Case You Missed It: Product Updates from 2023

Drilling Analytics

Corva's Slide Sheet App Reveals Major Overhaul for Slide Sheet

Accurate slide detection and information is critical to optimizing drilling operations. Leveraging our customer’s feedback, Corva drastically improved its Slide Sheet app with several updates to the activity detector to increase sliding accuracy, and improve overall performance and scalability.

The user interface and experience has also been significantly redesigned and includes features such as Metric Charts, with additional filtering, and an option to expand each survey as an individual line item with tabular and graphical displays of Tool Face, Dogleg Severity, Build Rate and Motor Yield.

Input Custom Curves and Plans in Days vs Depth (DvD)

The DvD app now supports customer input of custom curves and plans to enable referencing of multiple additional scenarios. Well sections can be specified in the plans and can be highlighted using app filters. In addition, the DvD app now supports a higher resolution sampling time, allowing for time increments as low as 5 minutes!

Tripping Speeds Now Includes Time Mode

Check out the newly added Time Mode feature in Corva’s most popular and effective app for improving drilling operational performance, Tripping Speeds. Customers can now toggle between Time and Speed modes for improved decision-making.

If you are looking to exclude Restricted Operations for increased operational visibility, check out the option from Tripping Speeds calculations and graphically distinguish between tripping and connection times.

Real-Time (Live) Data

Explore Your One-Stop-Shop for Mud Properties

In 2023, Corva replaced the Mud Weight vs. Density app to create a single, powerful one-stop shop for mud properties. The Mud Properties app now accesses all mud properties available in Corva versus depth. With added support for offshore rigs, narrow mud windows can be easily viewed.

Offset wells are more easily accessed to quickly compare fluid checks across dozens of wells, including high-performing wells. Other benefits include better monitoring of the mud system being in tolerance and ensuring that the mud program progresses as expected.

Enhance Data Monitoring of Critical Operations

Bring key, user-selected, real-time drilling data to the forefront on your dashboard to increase awareness for critical safety and operational decisions with the Data Monitoring app. This app is a single-trace, real-time data viewing app where user-selected high and low limits can be set and color-differentiated as visual alarms.

The app is well suited for enhanced monitoring of critical operations such as well control and fluid transfers and volumes, both on the rig and in remote operation centers.

New Horizontal Orientation in the Traces App Supports Complex, Multi-Stage Operations

In response to customer feedback, Corva’s benchmark Traces app has been updated to add a horizontal orientation view. This view better supports complex, multi-stage operations, such as monitoring pressures and volumes for cementing offshore wells.

The horizontal view also better aligns with remote operating centers to provide more display efficiency and adapt to wider screens.

Flagship Drilling App, Hookload Broomstick, Now Includes Offset Well Selector

One of Corva’s flagship drilling apps for assessing wellbore conditions just got better! To enhance the functionality of the Hookload Broomstick app, the Offset Well Selector has been added to the app to easily visualize comparable wells’ broomstick plots rather than uploading a static model. You can now also monitor the current trip to compare slack-off and pick-up points against the previous BHA.

Fingerprinting Adds Two New Metrics: Annular Back Pressure and Flow-Out Percent

Corva’s Fingerprinting app is key for monitoring well control issues and particularly for ensuring that Managed Pressure Drilling (MPD) systems and rig pumps are synchronized to prevent critical losses or influxes. Two new metrics, Annular Back Pressure and Flow-Out Percent, have been added to allow for more comprehensive monitoring during pumps-off events, including connections and flow checks.

Let's Talk Data Quality

Data Quality Visibility in Drilling

In 2023, Corva implemented a key new platform called Fusion that is dedicated to customer’s data quality. Fusion provides customers with full transparency of their data quality levels along with the up-to-date status of actions taken to address and mitigate data quality issues by our 24/7 Operations team. To facilitate access to data quality, Data Quality Badges were added to Drilling apps to quickly show data health score, which is calculated based on real-time data quality rules affecting each app. Access your Data Quality page within each app to gain a comprehensive overview and detailed breakdown of data quality issues and actions to resolution.

Are you still emailing us PDFs daily? Let’s move to seamless ingestion and automation in 2024 and boost your data quality! Contact James Jerry to learn more on how we can connect your data in a matter of minutes to days, from key reports and systems such as:

- Surveys

- Mud reports

- DDRs, and

- Vendor data or reporting systems (i.e. WellView, OpenWells, and WellEZ)

Schedule Time with Solutions Engineering Team