Corva extends track record of digital transformation for drilling with release of hydraulic fracturing data analysis tools, enabling oil & gas producers to optimize frac performance, avoid hazards, and cut costs using big data and real-time monitoring.

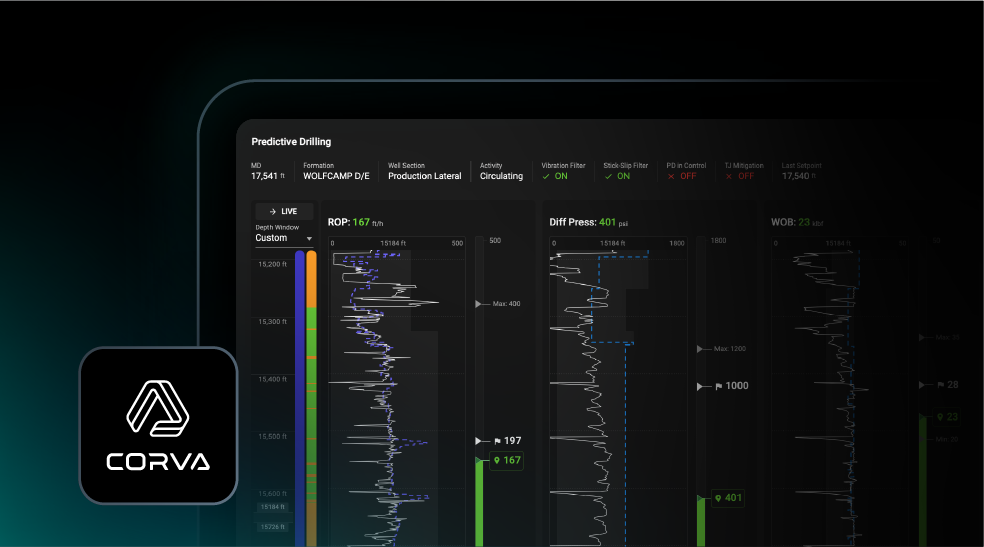

Corva, the leader in real-time drilling analytics, announces the launch of its frac optimization platform, a software suite of 20 mobile and web apps that gives engineers real-time insight into hydraulic fracturing operations. Corva’s latest innovation brings much-needed analytical capabilities and decision support to one of the most critical processes in the energy industry, enabling producers to improve frac performance, optimize production, monitor by exception, and avoid the hazardous pressure conditions that can damage nearby wells. The introduction of real-time frac analytics extends the company’s existing drilling optimization platform of more than 60 apps, for which it recently reported explosive customer growth and aggressive hiring to meet demand. The announcement was made at the Unconventional Resources Technology Conference (URTeC), being held this week in Denver. For more information or to view a live demonstration of Corva’s frac analytics, please stop by booth 116 at URTeC or visit FracMagic.com.

“We are laser-focused on operational excellence and capital discipline for our D&C operations. The data and real-time analytics that we receive from Corva have been an important tool to Diamondback as we continue to drive drilling performance and reduce capital costs,” said Mike Hollis, President and COO of Diamondback Energy (NASDAQ: FANG).

Increasingly tight well spacing, multi-stage fracturing, and variations in subsurface rock fabric create unique challenges for every new horizontal well. To tailor hydraulic fracturing treatments for optimal results, completion staff must be able to quickly analyze and respond to constantly changing conditions during a frac operation.

Corva’s real-time frac optimization platform enables oil & gas companies to:

- Optimize design and costs using best-in-class parameters from historical data.

- Identify landing zones for laterals and select optimal stage treatments.

- Prevent frac hits by alerting staff to hazardous pressure build-up on nearby wells.

Key features of Corva’s new frac optimization platform include the ability to compare stage design with actual, analyze nearby wells for optimal parameters through the same formation, track proppant concentration, and monitor zipper frac operations. Additional functionality includes automated frac activity detection and monitoring algorithms, eliminating the need for completions and back office staff to manually share status and alerting users when action is needed.

“Horizontal wells and the widespread use of hydraulic fracturing are the powerhouses driving the North American shale revolution, yet the benefits of the digital oilfield just haven’t manifested for drilling and completions as they have for exploration and production,” said Ryan Dawson, Corva’s founder and CEO. “Corva has brought much-needed innovation and digital transformation to drilling, which is disrupting the oil & gas software market in a positive way and is why we have seen massive uptake of our real-time drilling data analytics, now used on more than 150 rigs to accelerate rate of penetration, optimize directional drilling, and cut capital costs by millions,” Dawson elaborated. He added, “Corva is scaling its vision of the digital oilfield by bringing the same level of innovation to bear on the unique data consumption needs for completions, giving engineers powerful new tools to optimize every lateral and stage, keep trucks pumping longer through complex zipper fracs, and optimize treatments for maximum production returns.”

Bringing Digital Transformation to Unconventional Problems

Hydraulic fracturing is a multi-day process that can involve dozens of pumping trucks. Large volumes of data are generated throughout the process, including pressures, flow rates, proppant levels, and data for nearby wells. Increasingly, engineering staff must analyze and adjust frac operations in real-time to avoid costly downtime and avoid hazardous conditions. Real-time data analysis is especially critical for zipper frac operations, in which two wells are frac’ed simultaneously to enhance reservoir rock exposure through alternating-stage fracturing.

Corva’s advanced completion analytics and real-time engineering models are purpose-built to solve the challenges completions staff face in analyzing large volumes, wide variety, and high-velocity data, the “three V’s of big data. Corva also brought the benefits of digital transformation to horizontal drilling with the industry’s first real-time drilling optimization platform, which has been rapidly adopted by energy producers looking for new ways to drill faster, lower cost wells. Corva’s real-time drilling and completions platform is deployed on more than 200 rigs with customers that include 25 of the largest publicly traded oil & gas producers.